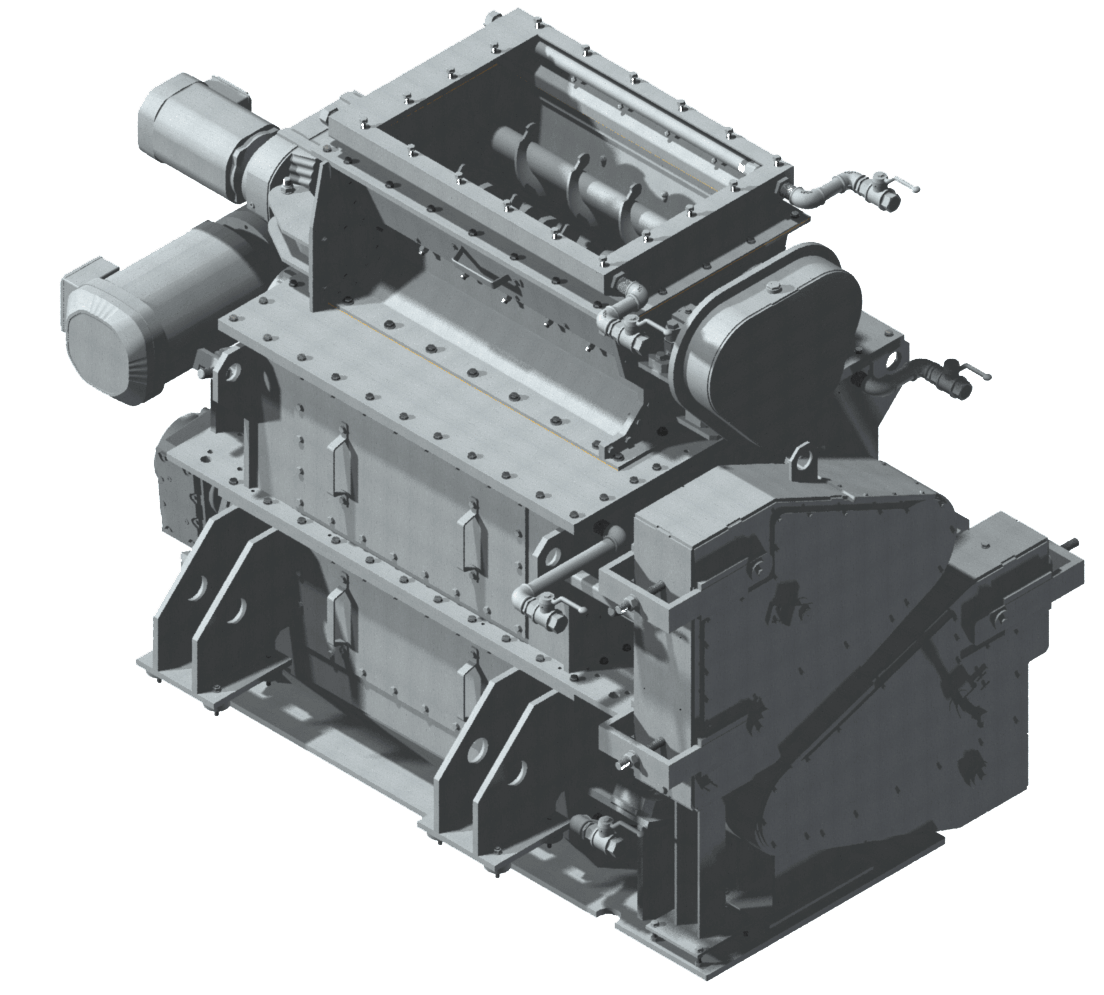

As to bulk goods conveyor technology we supply great services – starting from the planning and construction via production up to erection and maintenance. Future-oriented conveyor technology and individual solutions combined with high quality.

Optimizing of older plant

We recondition your plant und improve the reliability and operational life. A great share of the conveyor technology still used in production plant, factories and other fields was designed and constructed years ago. Due to increasing competition it becomes more and more important for companies, that machines work efficiently. Also the automation of technical processes and aspects, such as performance and operational life are of major concern. At this we can support you.

A highly-qualified team quickly and efficiently fixes emerging faults and disturbances, such as idleness or a malfunction on the spot. It will be our pleasure to inform you about the possibilities in regard to the reconstruction or the extension of your plant, so that it can cope with the increasing requirements.

Together with you we will draft an individual concept for the modernization of your conveyor system. In this process we will also consider the cost-effective-ness and we will be pleased to help with your decision, if it makes sense to refurbish your old plant or, if it might be more profitable to invest in a new conveyor system.