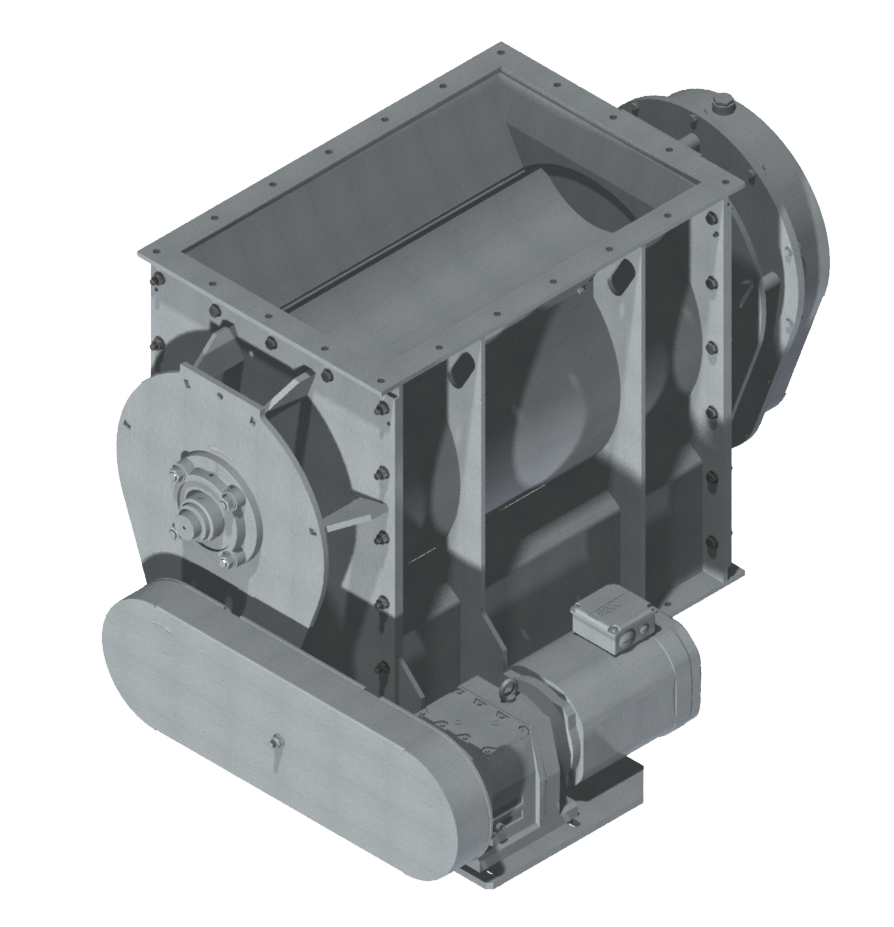

Rotary valve |

|

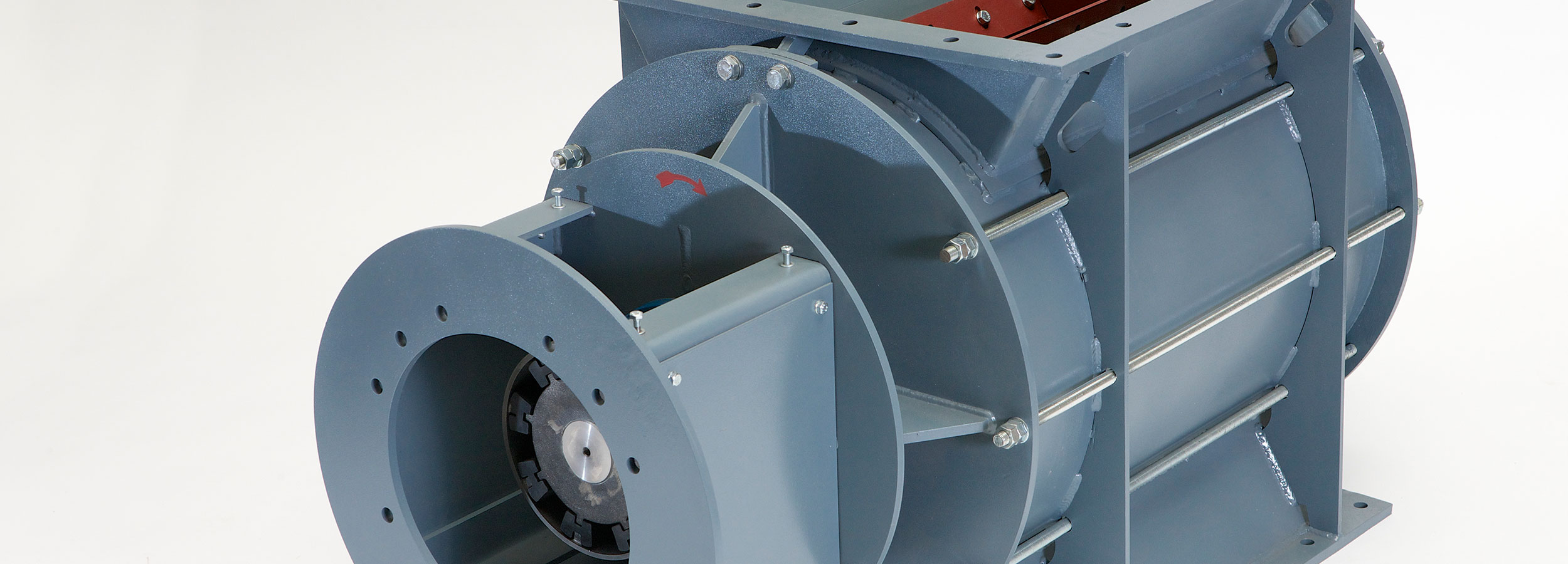

The SMD rotary valve is used below silos and bunkers in order to convey material to the down-stream conveying organs, such as the trough chain conveyor, the screw conveyor or the apron conveyor. Likewise the rotary valve is used in front of mixers, dryers and mills.

How does the SMD rotary valve work?

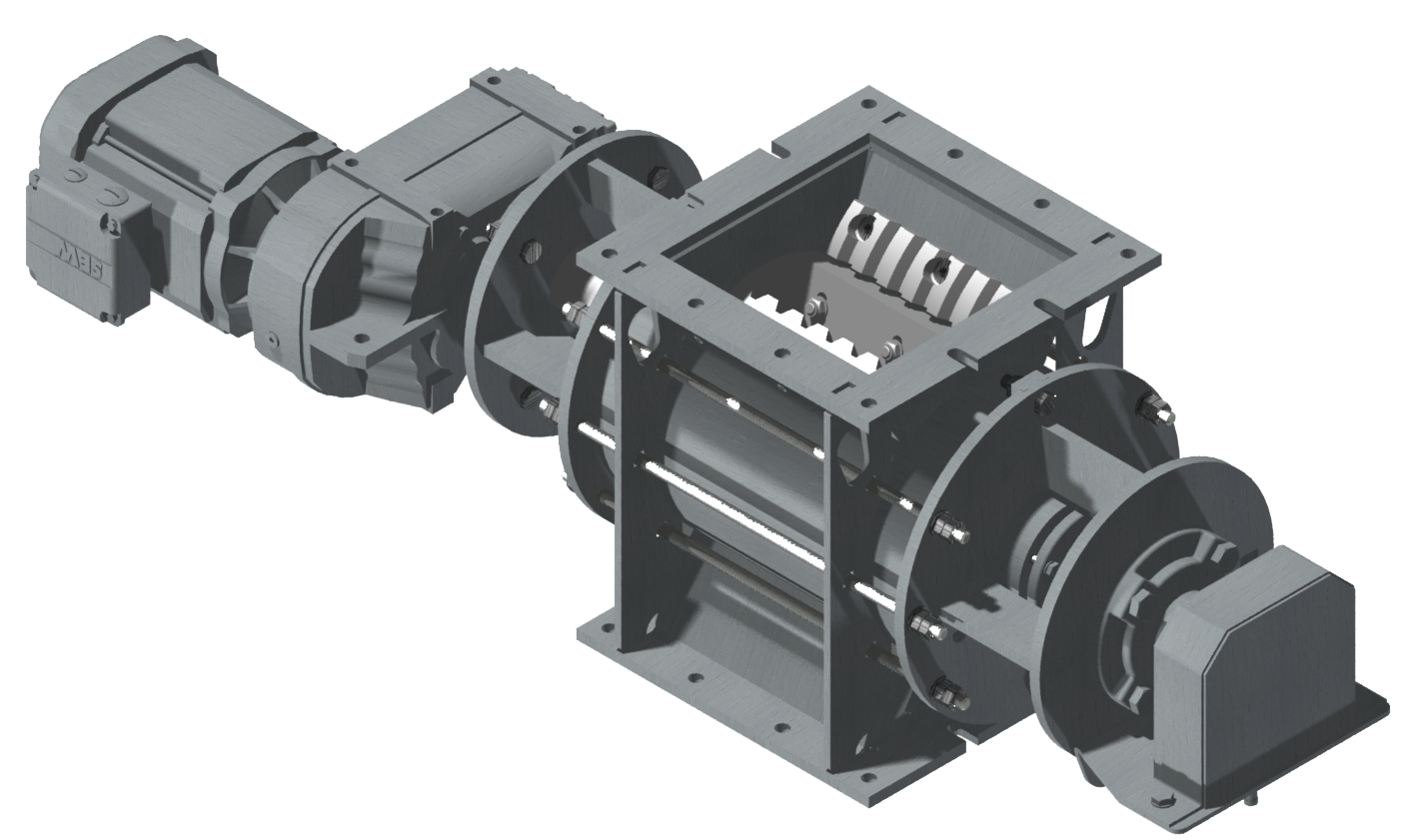

A rotor with rotor blades precisely turns in the rotary valve housing.

The area between the rotor blades forms a compartment. Each rotor cell takes in bulk materials below the inlet opening and dispenses it at the discharge opening.

This results in a volumetrically, continuous conveyance. The conveying performance can be determined according to the bulk material transported and the rotation speed of the rotor.

Certain differences in pressure are efficiently separated by the small tolerance between housing and rotor. The SMD rotary valve basically consists of a stury rotary valve housing, the rotary valve rotor and a drive unit. If abrasive bulk goods are to be conveyed the housing can be constructed with a special wear-resistant bush and the rotary valve rotor can be made of wear plates. Where grain has to be broken our rotary valve with break function or our knife feeder is applied. The SMD rotary valves are the optimal devices for the dosing, feeding or discharging of fine-grain or atomized products or granulates.

Crusher rotary valve |

|

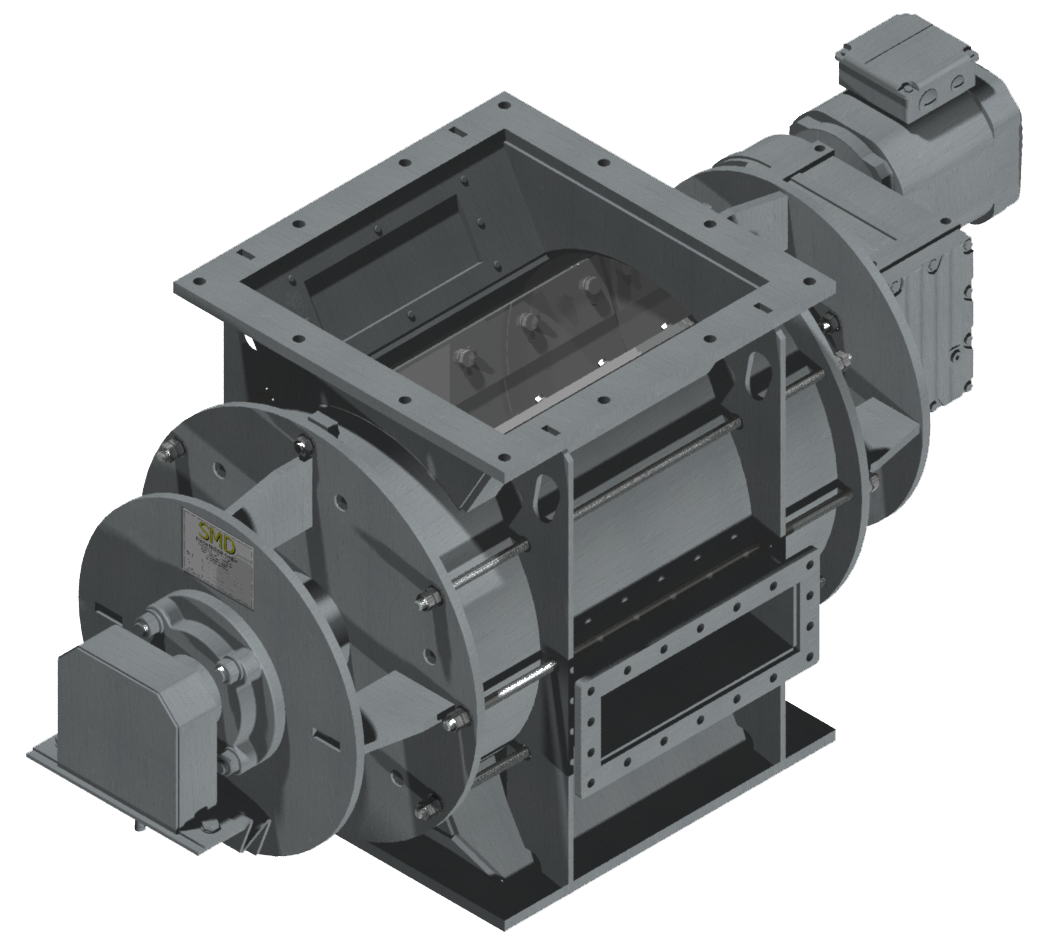

The SMD Crusher rotary valve is a design of the SMD rotary valve. It is used to break larger grains and over-sized bulk material, thus preventing the rotor from blocking. For this purpose, the ends of the rotor chambers are equipped with toothed strips. These rotate against a fixed toothed strip at the housing inlet and break the bulk material.

Rotary valve with cleaning device |

|

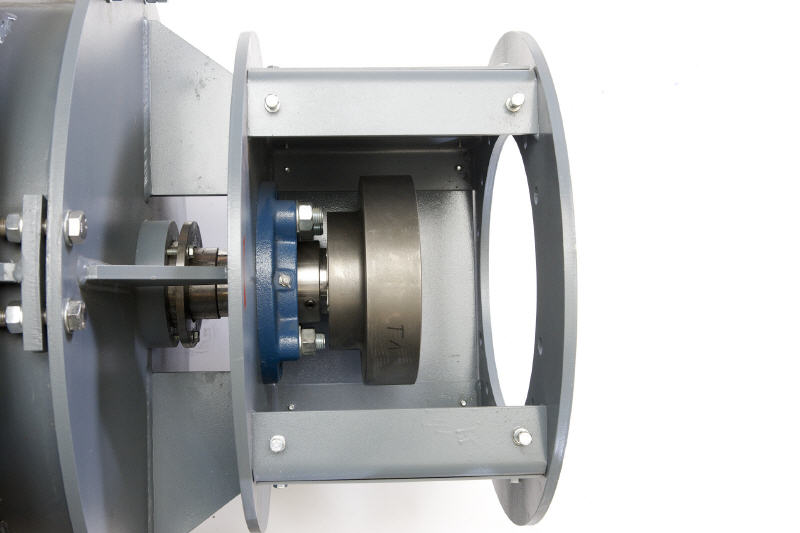

The SMD Rotary valve with cleaning device is a design of the SMD rotary valve. It is used for caking or slightly sticky bulk materials. A rotor with rotor blades and rounded chambers rotates precisely in the rotary valve housing. Below the rotor, a scraper wheel scrapes out the cells of the rotor and thus ensures smooth conveying of the bulk material.