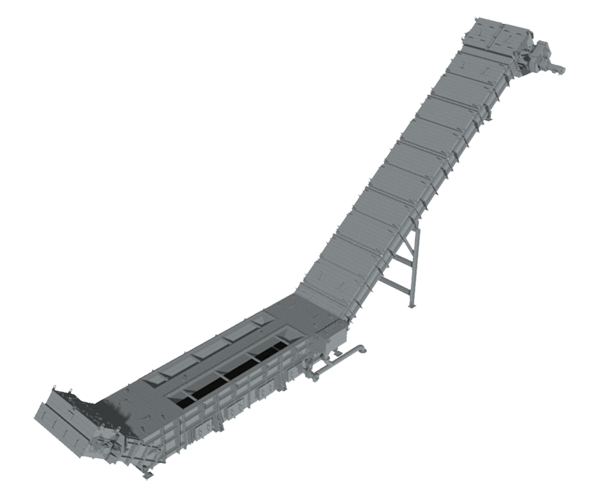

The SMD Similar to the SMD trough chain conveyor the submerged chain conveyor is designed individually. It can be used for the transport of any kind of combustion residues. It is compact, low-noise, highly wear-resistent and easy to maintain.

Similar to the SMD trough chain conveyor the submerged chain conveyor is designed individually. In doing so the manufacturing of a reliable, easy-to-maintain plant guaranteeing a long service life is our goal. This is realized by the usage of appropriate materials and an optimal layout of the line. In the material charging area(s) the layout of the lines are most horizontally, ascending to the material discharge point. The ascending trough section also serves as a drainage line.

Our drive- and tensioning stations are constructed easy to maintain. The housing of our drive station is designed devisible. This facilitates the replacement of the drive shaft during inspection. Likewise the complete shaft including chain wheels and bearings can be removed from the housing of the tensioning station. The individual plates of the SMD chain wheels are devisible. This minimizes the assembly effort and reduces the idleness of the plant.

For easy access during inspections and revisions all station covers are equipped with safeguarded quick-locking mechanisms. By using exterior pedestrial bearings we reliably prevent the intrusion of conveyed materials into the bearing location. Monitoring devices such as speed monitors and chain break- and chain tension surveillance are also comprised in our scope of supply. Due to the closed construction of the trough no materials conveyed can escape into the environement.

For easy access during inspections and revisions all trough covers can be taken off. In order to prevent extreme abrasion on the trough bottom a wear-resistent material coating can be installed optionally. Possibly installed guide wear rails can be screw-fastened to ensure a fast exchange. User-defined material discharge points are possible anywhere along the trough section and can be shut by the SMD slide gate.

The SMD trough chain conveyor can be supplied in a dustproof, pressure-tight version. The SMD trough chain conveyors are constructed as one-strand or two-strand conveyors with forged fork link chains. The SMD trough chain conveyor can be used multi-functionally. Wheel flakes, wet and dry sludge, tree bark, wood chips, slag, ash, fluff or wood left-overs can be reliably conveyed in different grain sizes